Let’s say you’re in your basement, ready to work on your home’s HVAC system. You have your flexible duct in hand, and it’s time to install it so that cool or warm air flows smoothly throughout your house. Don’t worry—it’s not as hard as it seems. We’re here to help you out with how to install flexible ductwork.

Flexible ductwork is a key part of your HVAC system. It carries air from your HVAC unit to different rooms in your home. No matter if you’re adding new ducts or replacing old ones, you can do it yourself with just a few simple tools.

Simply put, to install flexible ductwork, —

- measure and cut the duct,

- connect it to the vents or ducts,

- secure it with tape or clamps,

- and support it with hangers.

In this blog, we’ll show you exactly how to install flex ductwork. We’ll go step-by-step, keeping things easy and realistic.

Let’s get started!

Key Takeaways

|

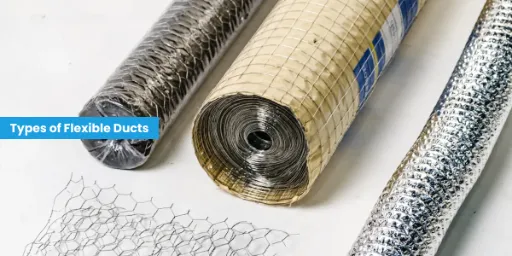

Types of Flexible Ducts

There are different types of flexible ducts, each made for specific needs. Here’s a quick look at them:

- Insulated Flexible Duct: This duct has insulation around the inside, which helps keep the air at the right temperature as it moves through the system. It’s great for saving energy and making your HVAC system work better.

- Non-Insulated Flexible Duct: This one doesn’t have insulation, so it’s cheaper. It’s good for areas where temperature control isn’t as important.

- Ultra Flexible Duct: These ducts are made for tight spaces. They are extra bendy and strong, so they work well when there isn’t much room to move around.

Each type is made for different situations, so choose the one that fits your needs best!

How to Install Flexible Ductwork

| The Four Rules for Flexible Ducts

There are four simple rules you should follow to ensure flexible ductwork performs its best: Don’t overstretch it. Avoid sharp bends. Support the duct properly. Seal all joints and connections. |

Okay, let’s get to the installation. Here’s a breakdown:

1. Gather Your Tools

Before you begin, make sure you have all the right tools:

- Flexible duct

- Duct connectors or clamps

- Duct tape or zip ties

- Measuring tape

- Scissors or a utility knife

- A saw (for cutting rigid duct, if needed

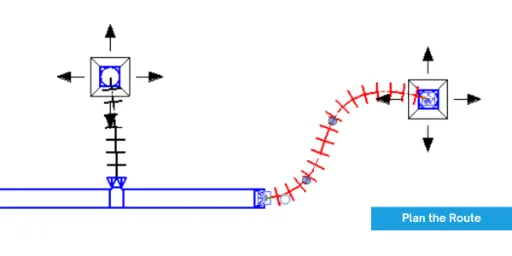

Step 2: Plan the Route

First, plan where your flex duct will go. Aim for a straight path to make airflow easier and your HVAC system more efficient.

Measure the distance from the HVAC unit to where the air needs to go. Try to avoid sharp bends because they can slow down the airflow.

3. Measure and Cut the Duct

Measure the length of ductwork needed. Add a little extra to avoid cutting it too short. Then, use scissors or a utility knife to cut the flex duct to the correct size.

How to Size a Flexible Duct

Sizing the duct correctly is very important. If it’s too small, the air won’t flow properly. If it’s too big, it can waste energy.

Here’s a simple guide:

| Duct Diameter | Air Flow (CFM) | Typical Use |

| 4 inches | Up to 150 CFM | Small rooms |

| 6 inches | Up to 250 CFM | Medium rooms |

| 8 inches | Up to 400 CFM | Larger rooms |

You should always check the HVAC system’s requirements before choosing the duct size.

4. Attach Duct to Vents or Ductwork

Now, it’s time to connect your flexible duct to the vent or existing duct. Slip one end of the flex duct over the vent or rigid duct. Make sure it fits snugly. Secure it with duct tape or a zip tie.

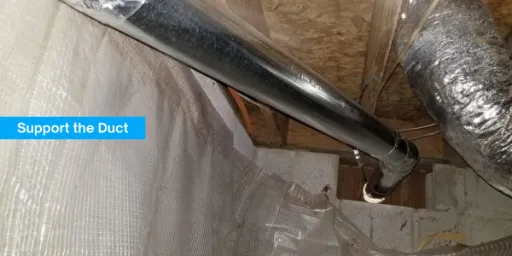

5. Support the Duct

Flexible ducts should not hang freely. Use hangers or straps to support the duct. This will prevent it from sagging or getting damaged.

How to Make Connections

To make sure your ducts work well, you need to connect them the right way. Here’s how you do it:

How to Connect Flex Duct Together

When connecting two pieces of flex duct, overlap the ends by about 3-4 inches. Then, use duct tape or clamps to secure the connection. Make sure it’s tight so air doesn’t leak out.

How to Connect Flex Duct to Rigid Duct

To connect flex duct to rigid duct (like metal or PVC), you need a connector. Put one end of the flex duct into the connector and secure it with duct tape or a clamp. This will keep the connection tight and airtight.

How to Connect Flex Duct to Metal Duct

When connecting a flex duct to a metal duct, use a metal connector. Slide the connector over both the flex duct and the metal duct. Then, secure it with screws or a clamp. Don’t forget to seal it with duct tape to stop any air leaks.

How to Get Even Better Performance with Flex Duct

To get the best performance from your flexible ductwork, follow these simple tips:

Minimize Bends

Avoid sharp turns and bends. Sharp bends slow down airflow and make your system less efficient.

Use the Right Size Duct

Make sure the size of your flex duct matches the airflow needs of your HVAC system. Ducts that are too small can block airflow, and ducts that are too large can make your system work harder.

Insulate the Ducts

Insulating your ducts helps keep the air at the right temperature. It also stops air from being lost due to temperature changes, especially if your ducts run a long way.

Support Your Ducts

Hang your ducts properly every 4 feet or so with hangers or brackets. This keeps them from sagging, which can block airflow.

Besides, if you want, you can check out this informative blog to learn how to install return air duct in wall.

How Long Does Flexible Ductwork Last?

Flexible ductwork usually lasts anywhere from 10 to 20 years. However, this depends on factors like installation quality, usage, and maintenance. Proper installation and sealing will make it last longer.

What Steam Express Can Do for You?

Steam Express doesn’t just clean air ducts – we also offer professional air duct installation and repair services. No matter if you need new ducts installed or old ones fixed, our experienced team is here to help.

We ensure proper installation for better airflow and energy efficiency, and we quickly repair any damage to restore your system. Trust us to make your home’s air quality better, no matter the issue.

Call Steam Express for expert air duct services today!

Wrapping Up

Hopefully, coming to this point, we can assume that you now have a pretty good idea of how to install flexible ductwork. Installing flexible ductwork doesn’t have to be complicated.

By following the steps and best practices in this guide, you can have a working duct system in no time. Remember to measure, support, and seal properly to get the best performance.

If you take care of your flex ducts, they’ll last for many years.